APPLICATIONS

Agricultural Heating Uses

- Swine farms

- Poultry houses

- ASF disinfection drying system

ADVANTAGES

- Substantially reduce fuel consumption during heating time;

- Energy saving is between 30% and 60%;

- Air temperature is uniformly distributed, and flocks evenly scattered;

- Reduces ammonia and carbon dioxide, improving the air quality of breeding houses;

- Keeps feces dry, reduces need for bedding materials, decreases pseudo-podium and hock burns;

- Increases weight and FCR;

- Positions control for air exchange to avoid heat loss.

HOW IT WORKS

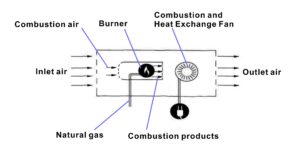

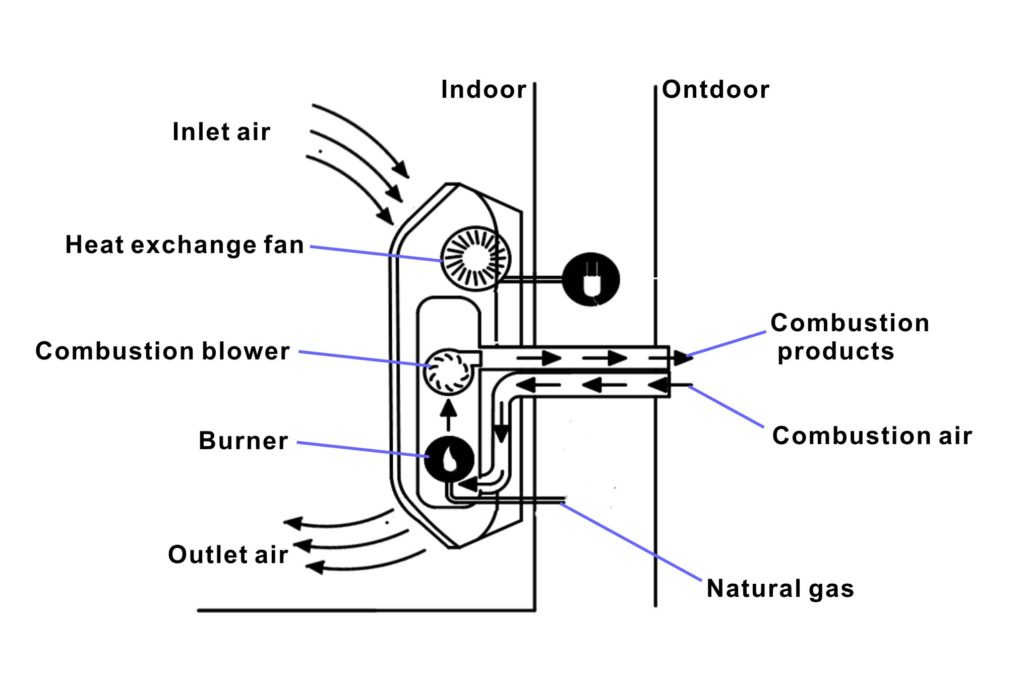

This product is developed as a sustainable solution for the animal husbandry industry. By integrating the function of air intake and air exhaust, it is particularly suitable for environments which need a large amount of fresh air from outside. Meanwhile, it greatly improves the breeding environment and effectively solves the contradiction between ventilation and heat loss.

There are two fans inside of the heat recovery ventilator, one discharges the humid air in the room while another intakes fresh cold air from outside. When hot air and cold air passes through the heat exchange core, the fresh air is preheated, which can reduce the cost of heating and minimize cold stress.

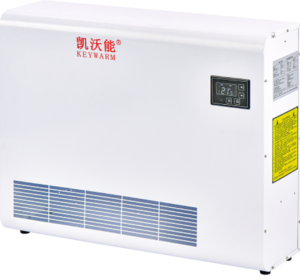

- Air flow: 2×2,500m3/hr

- The box material is Zinc Aluminum Steel;

- Both air inlet and outlet are filtered by primary filter (easy disassembling and cleaning) to prevent blockage of the heat exchange core and guarantee the quality of fresh air from outside;

- Aluminum alloy spherical air outlet is adopted for the fresh air inlet, with the long distance of air blowing, omnidirectional wind can be adjusted with 180-degree angle, ensuring no dead point of air supply;

- Excellent heat transfer performance and high heat transfer efficiency, special anti-corrosion treatment, durable, easy to disassemble and clean;

- The exhaust fan and inlet fan can tolerate multiple environments, like high-humidity and corrosion breeding houses;

- Automatic defrost prevents the heat exchange module from being blocked, and the defrost time can be set automatically according to the actual temperature conditions;

- Fitted with an environment controller which can be automatically turned on and turn off;

- Solid and reliable structure, easy to disassemble and repair.

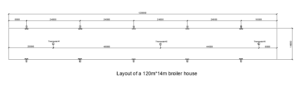

Select the number of heat exchangers at the maximum load to meet the minimum ventilation for Stage 1 and/or Stage 2. For all-in, all-out livestock houses, this varies as the animals grow. Determine the number of heat exchangers (maximum airflow) by adult animals and run the appropriate number of heat exchangers (reduced airflow) for young animals.

The biggest challenge facing heat exchanger application in a poultry house is the amount of dust

encountered in the air. Dust in the exhaust airstream, if not handled properly, will degrade the

performance of any heat recovery system. Proper handling of dust is critical to the success of a heat

recovery system application. Traditional flatplate heat exchangers require upstream filtration systems

on the warm exhaust air side to intercept the dust (from indoor air) before it enters the heat exchangers.

After a growout, exchanger cores need be cleaned using compressed air or water, depending on the

equipment designs. Regular cleaning effectively removes dust and rejuvenates the cores.