Gas infrared heater are revolutionizing the way heating systems function in various industries and settings, offering innovative solutions that balance efficiency, comfort, and cost-effectiveness. These systems have become indispensable in applications ranging from industrial warehouses to agricultural settings, ensuring reliable and targeted heating wherever they’re installed. This blog explores the significant role that gas infrared heaters play, how they differ from traditional heating systems, and the technological advancements driving their adoption.

Table of contents:

How Gas Infrared Heaters Provide Consistent Heat Distribution

Cost Savings Through Low-Intensity Gas Infrared Heating

Comparing Infrared Heaters with Indirect Air Heaters for Efficiency

How Gas Infrared Heaters Provide Consistent Heat Distribution

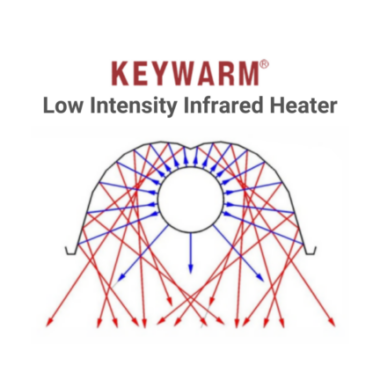

Gas infrared heaters rely on radiant heat, spreading warmth directly to objects and surfaces rather than just heating the surrounding air. This direct approach ensures even heat distribution, which is a critical advantage in environments where consistent temperatures are necessary, such as warehouses, gymnasiums, and factories. Unlike traditional warm air systems, gas infrared heaters reduce air stratification—preventing the phenomenon where warm air rises and cooler air remains at ground level. By targeting specific areas, these heaters maintain uniform warmth across large spaces, offering a sensation of instant heat comparable to standing in sunlight. This feature is especially valuable for spaces with high ceilings or drafts, where traditional warming methods often fall short.

Cost Savings Through Low-Intensity Gas Infrared Heating

One of the most attractive benefits of gas infrared heaters is their ability to reduce energy consumption while maintaining efficient performance. Low-intensity vacuum infrared heaters, such as those in the LTV series, provide annual savings of up to 25–35% in natural gas or propane usage compared to traditional warm air systems. This cost efficiency is driven by the heater’s ability to deliver immediate and focused warmth with minimal energy loss. Another factor contributing to cost savings is their simple installation and maintenance. With no moving parts like fans or blowers, these heaters require less upkeep than indirect air heaters or other conventional systems, cutting down on long-term maintenance costs. For instance, heaters utilizing sealed combustion can often vent outdoors efficiently and safely, reducing the need for complex piping or heat-distribution networks.

Comparing Infrared Heaters with Indirect Air Heaters for Efficiency

The efficiency of gas infrared heaters often surpasses that of indirect air heater in specific applications. Unlike indirect air heaters, which rely on warming air and circulating it throughout the space, gas infrared heaters directly heat objects and people within their radiant path. This direct heating method ensures minimal heat loss, allowing for better energy conservation. Furthermore, the absence of air circulation in gas infrared heaters decreases the spread of dust and allergens—making these systems ideal for settings where hygiene is critical, such as poultry farming or food production. Poultry heaters, in particular, benefit from the predictable and immediate warmth provided by gas infrared units, ensuring optimal conditions for livestock. Indirect air heaters, while effective in some scenarios, often struggle to deliver the same level of precision and energy efficiency, especially when heating vast or unevenly ventilated areas.

Innovations in Gas Infrared Heater Technology

The technological advancements in gas infrared heaters have further solidified their position as a staple in modern heating systems. Units like the Low-Intensity Vacuum Infrared Heater (LTV series) incorporate cutting-edge features such as high-polished aluminum reflectors, designed to maximize radiant efficiency. These reflectors ensure better heat dispersion, reducing the energy required to warm the targeted area. Reliable direct spark ignition systems with 100% gas valve shut-off mechanisms improve both safety and operational reliability. Additionally, new models are crafted from premium materials like heat-treated aluminized steel and powder-coated burner housings, which enhance both the longevity and efficiency of the heaters. Multiple burner systems allow for better coverage in large spaces, with various radiant tube configurations available to suit the area’s specific heating requirements. Advances such as sealed combustion and customized venting options also enable these heaters to meet the demands of settings with unique safety or environmental concerns, from factories to churches and auto repair shops.

The combination of consistent heat distribution, reduced energy costs, and cutting-edge technology makes gas infrared heaters an indispensable component of modern heating solutions. Businesses using these heaters can expect lower operational costs, better comfort levels, and increased safety compared to traditional systems like indirect air heaters. Whether improving working conditions in industrial spaces or creating optimal environments for livestock and poultry, the versatility and efficiency of gas infrared heaters ensure they remain a top choice for forward-thinking enterprises.