APPLICATIONS

Industrial Heating Uses

- Warehouses

- Factories

- Auto repair shops

- Churches

- Gymnasiums

- Drying process

ADVANTAGES

- Annual natural gas and propane consumption savings of up to 25-35% compared with traditional warm air systems.

- No need for a heat-distribution system.

- High comfort level, recommended even in places with drafts and high ceilings.

- Easy maintenance, without moving parts such as fans or blowers.

- Simple to control with a commercial or digital thermostat.

- Superior efficiency thanks to direct heating; no loss of heat through piping.

- Reduced air stratification.

- Sensation of instant heat.

- Quiet operation.

HOW IT WORKS

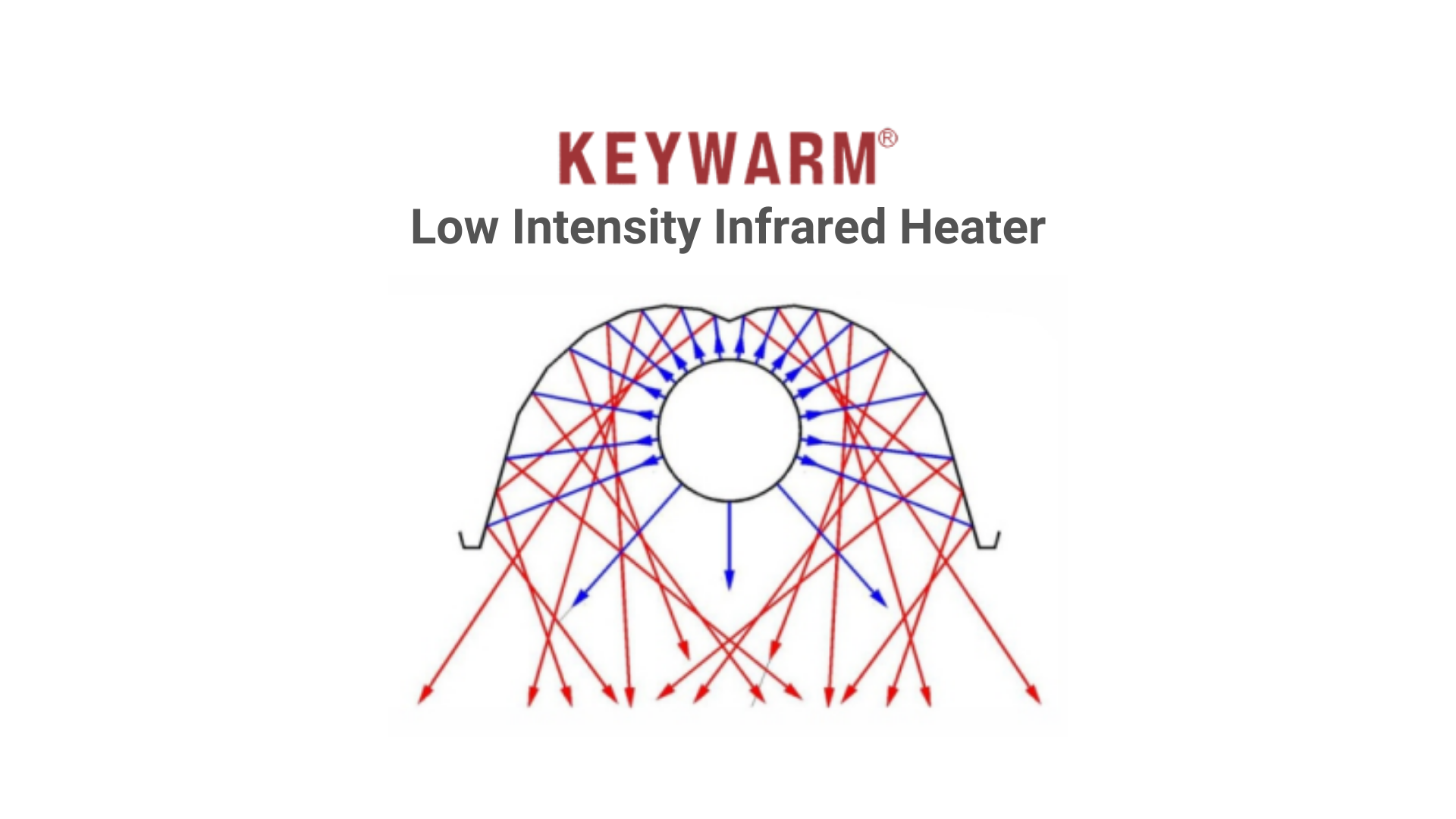

A low intensity infrared unit heats by radiant heat. The energy is spread by radiation: its effect on the human body is rather like being exposed to the sun. Like the light from a lamp, infrared radiant heat is directional and warms every object in its path, depending on the nature of its surface. The infrared radiant heat traverses the ambient air without losing its energy until the moment it meets an object.

Primary and secondary air and gas mix into the burner cup to create a long flame combustion in the radiant tube. The radiant surface temperature can reach 500°C but the far end radiant tube’s temperature is lower than 200°C.

- A blower the end of the radiant tube “pulls in” air from the burner at the front to mix with the gas, and the burned flue gas passes through the radiant tube and is finally discharged from the same blower at the end. The combustion chamber is a negative pressure, so it is called a vacuum system;

- Natural gas or LPG;

- Rates 10/20/35/40/50kW;

- Radiant tube length of 3/6/9/12/15/18 meters are available in straight, U and L configurations;

- Multiple burners can also share a fan to realize the combination and arrangement of various radiant tubes, which is convenient to cover the heating area and reduces the number of wall holes passing through the exhaust gas;

- Powder coated steel burner housing;

- Heat treated aluminized steel radiant tube.

- Reliable Direct Spark Ignition with 100% gas valve shut off.

- High-polished aluminum reflector maximizing radiant efficiency (Keywarm is 100% reflection). Side or bottom reflector available.

- Horizontal or 45° reflector mounting.

Heating Power:

- Warehouse: 80-110 W/sqm

- Factory: 120-180 W/sqm

Combustion: Sealed combustion (the combustion air is taken directly from outside but mostly from the space to be heated)

Venting: The combustion products can be vented indoors or outside but mostly outside for multiple burner system.

- Minimum height to be respected, according to each manufacturer.

- Installation is not recommended in places where there are chlorine products, solvents or explosives, but certain models are suitable for that type of environment.

- The combustion products are vented indoors with additional ventilation. Usually, this calls for an interlock between the appliance and a mechanical extractor fan. A fresh air supply unit needs to be installed in order to maintain an acceptable level of CO2 (5,000 ppm). For more details, consult the manufacturer’s Installation Guide.

- The ventilation rate stipulated in Code B 149.2 is 300 ft3 of air per minute per 100,000 Btu/hr or each kW per 22m³/h fresh air of high intensity infrared installed.