Managing a successful poultry operation requires maintaining the right environment for your flock. An essential aspect of this is proper heating, especially in high-density poultry farms. The use of indirect air heaters has emerged as a game-changer for poultry producers looking to optimize operations while ensuring the health and productivity of their birds. This blog explores how indirect air heaters improve biosecurity, enable consistent growth, and protect your poultry with clean air circulation.

Table of contents:

Enhancing Biosecurity Measures in Poultry Farms with Cleaner Heating

Why Indirect Heaters Are Essential for High-Density Poultry Operations

Ensuring Consistent Growth Rates Through Optimal Temperature Regulation

Protecting Poultry Health with Contaminant-Free Air Circulation

Enhancing Biosecurity Measures in Poultry Farms with Cleaner Heating

Biosecurity is a top priority for poultry producers, and indirect air heaters provide an effective solution to prevent airborne contaminants from affecting your flock. These heaters operate using a closed combustion system, which ensures that harmful gases such as carbon monoxide and nitrogen dioxide are kept out of the poultry enclosure. By only circulating clean, heated air, an indirect air heater minimizes the risk of respiratory issues and disease outbreaks caused by poor air quality. For operations focused on maintaining strict biosecurity protocols, this heating solution provides a significant layer of protection without compromising performance.

Why Indirect Heaters Are Essential for High-Density Poultry Operations

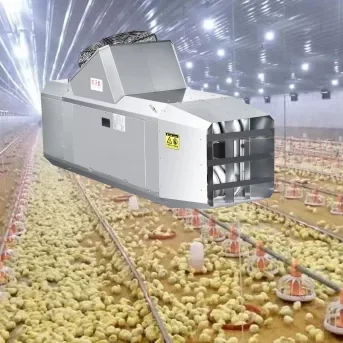

High-density poultry operations require efficient, reliable, and clean heating solutions to maintain optimal conditions and keep birds healthy. Traditional direct combustion systems often release pollutants into the environment that can harm birds, but indirect air heaters eliminate this concern by separating combustion gases from the warm air delivered into the space. The result is a safe environment conducive to the health and productivity of the flock. Additionally, the energy-efficient design of these heaters helps poultry farms lower operational costs. With options like the KeyWarm Indirect Fired Space Heater, you can achieve superior heating performance tailored to the unique demands of high-density operations.

Ensuring Consistent Growth Rates Through Optimal Temperature Regulation

Temperature regulation is critical to the growth and development of poultry. Indirect air heaters provide precise temperature control that allows you to create the ideal environment for every stage of production—from brooding to finishing. These systems distribute heat evenly, ensuring there’s no extreme variation in temperature that might stress your flock or impact their growth rates. For example, the highly accurate thermostat controls in KeyWarm’s livestock heater allow farmers to maintain consistent temperatures, creating an environment where birds can thrive. Consistent heating directly contributes to higher growth rates, better feed conversion, and overall flock efficiency.

Protecting Poultry Health with Contaminant-Free Air Circulation

Air quality is often overlooked in poultry operations but plays a critical role in preventing respiratory issues. Indirect air heaters ensure that only clean, contaminant-free air is circulated within your operation. Unlike direct combustion heaters, which can release moisture and harmful gases, indirect air heaters like the ones offered by KeyWarm prioritize your flock’s health by using advanced heat exchangers that eliminate such risks. Additionally, these systems reduce the buildup of harmful bacteria and viruses, helping to maintain a healthy and productive flock. This clean air circulation not only benefits the welfare of your birds but also leads to improved productivity and reduced mortality rates.

Investing in the right heating and air circulation systems is crucial for the success of any poultry operation. Indirect air heaters, like those provided by KeyWarm, offer a reliable and efficient solution for creating an optimal environment for your flock. By maintaining consistent temperatures and ensuring clean, contaminant-free air circulation, you can enhance bird health, boost productivity, and reduce operational risks. Prioritizing these advanced systems not only improves your overall profitability but also reinforces your commitment to animal welfare and sustainable farming practices.