APPLICATIONS

- Livestock farm cleaning

- Oil and gas industries

- Food services

- Truck&Car wash

- Construction sites

- Waste management industries

ADVANTAGES

-

Best cleaning solution for oils, grease and proteins, especially stubborn dirt.

- Improves emulsification, making it very easy remove.

- Reduction of the working pressure, cleaning time and the amount of detergent required.

- Cost savings and environmental friendly.

-

Shorter surface drying time.

- A significant reduction in germs so improved hygiene.

- Time saving of up to 35% with improved cleaning results and elimination of detergent expenses can quickly compensate the initial cost of a hot water boiler.

HOW IT WORKS

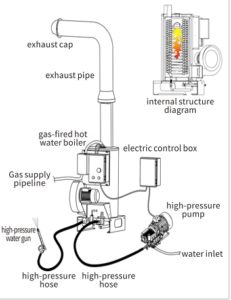

The water gun(s) start first, when high pressure water passes through equipment’s heat exchanger, the thermostat calls for ignition. Then the combustion fan starts to pre-purge. The ignition control system starts to ignite and burn after the safety inspection. The high-temperature flue gas heats the heat exchanger, and the heat exchanger absorbs heat and transfers it to high-pressure water to produce high-temperature, high-pressure hot water. The combustion will stop when water temperature reaches the thermostat set-point during washing or when the water gun(s) stop.

High-Pressure Cleaning Boiler – Industrial-Grade Cleaning Efficiency

Our high-pressure cleaning boiler is designed for industrial cleaning applications, providing powerful steam and high-pressure water cleaning for livestock farms, oil and gas industries, food processing, vehicle wash stations, construction sites, and waste management facilities. Built for maximum efficiency, this system ensures cost-effective, eco-friendly, and time-saving operations.

As trusted industrial heating experts, we also provide tube infrared heaters, Schwank infrared heater alternatives, and ceramic infrared heaters to meet various industrial and commercial demands. Our products prioritize energy efficiency, safety, and reliability in all environments.

Looking for a high-performance cleaning boiler with bulk ordering and worldwide shipping?

Contact us today for a custom quote!

- Heat exchange system: High efficiency heat exchanger with double-layer coils. Galvanized or stainless steel pipes are available.

- Combustion system: Downward flame, two-loop heating, high efficiency and energy saving.

- , extremely low content of CO and other harmful oxides in the flue gas, and backfire avoided.

- All-round water protection: water pressure protection (over/low pressure), water flow protection (over/low flow), water temperature and high temperature protection, dry heating protection, etc.

- Combustion safety: Pre-purge and post-purge cycles. Ignition failure safety protection, accidental flameout protection, fan failure protection.

- Control system: 12VAC low-voltage ignition and 24VAC gas valve are safe and reliable, and is convenient for daily maintenance.

- Anti-rust treatment heat exchanger coil (stainless steel optional)

- Rear-mounted boiler, cold water flows through the pump then heated by the boiler, which avoids accelerated aging and damage the sealing of the pump.

- Easy maintenance and quick replacement of parts.

Heating Power, Water Flow Rate are two major factors of a boiler:

- 88kW, 15L/min.

- 105kW, 21L/min.

- 130kW, 30L/min.

Once your proper PSI value is established, based on the type of job you are completing, you can increase your boiler’s to cut down on cleaning time. Below are a few common PSIs used with various surface cleaning duties:

- Concrete cleaning: 3,000 to 3,500 PSI

- Car cleaning: 1,200 to 1,900 PSI

- Wood cleaning: 2,000 to 3,000 PSI depending on hard wood or soft

- Trucks and tractors: PSI of at least 1,800

- Livestock shelters: PSI of at least 3,000

- Decks, fences, and siding: PSI of at least 2,000

- Paint stripping, construction-site maintenance, graffiti removal: 3,200 to 4,200 PSI

Each boiler comes with following safe functions:

- Excess pressure is released by a safety valve.

- An exhaust gas temperature limiter turns off the system if the temperature istoo high.

- The flow switch starts the boiler if the quantity of water is sufficient and stops it if the quantity of water is insufficient.

- The pressure switch starts the boiler by reaching the minimum pressure.

- All safety devices mentioned before are connected in series. That means if one of the elements has a malfunction the boiler does not start. This guarantees the highest level of safety.

Details manual available upon request.