APPLICATIONS

Industrial & Commercial Heating Uses

- Factories

- Warehouses

- Airports

- Railway Stations

- Supermarkets

- Offices,

- Gymnasiums

- Schools

- Exhibition halls

- Drying process such as food and painting.

Agricultural Heating Uses

- Greenhouses

- Poultry houses

ADVANTAGES

- Can disperse or direct heating.

- Integrated design for easy installation.

- Fully automatic operation, no need for personnel on duty.

- Wide power range, from 100kW to 1400kW.

- No need for complex water systems, low equipment failure rate.

- Quickly addresses heating issues in large spaces, warehouses, etc.

- Broad fuel adaptability, suitable for gas, oil, and other fuels.

HOW IT WORKS

A warm air generator is a stand-alone appliance serving to heat a given space and capable of operating on propane, natural gas or diesel.

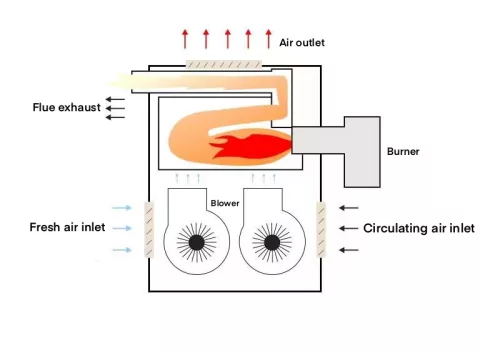

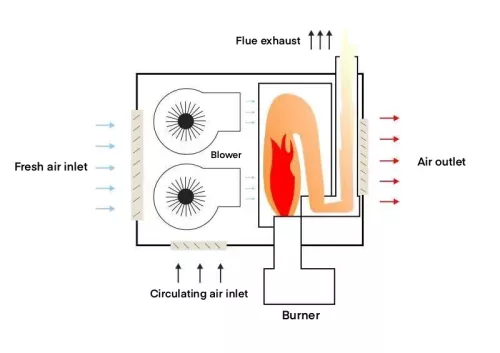

Drum-type indirect-fired air heaters mainly consist of a combustion unit, a heat exchange unit, a fan unit, a filtration unit, and a control system. They can be installed indoors or outdoors (with the option to install a mixed adjustment device for fresh air and indoor return air). Equipped with a built-in centrifugal fan, the system delivers heated air to the desired area through the air supply system, achieving the purpose of heating.

Vertical Configuaration Horizontal Configuration

Clean & Efficient Industrial Heating: KeyWarm Indirect-Fired Warm Air Generator (DIVI, DIVO, DIHI, DIHO Series)

The KeyWarm Indirect-Fired Warm Air Generator (DIVI, DIVO, DIHI, DIHO Series) delivers high-efficiency heating for industrial and agricultural applications. As leading industrial heaters manufacturers, KeyWarm offers a range of industrial heaters for sale, including ceramic heaters for sale, to meet diverse heating requirements. Our factory heaters are integral to comprehensive factory heating solutions, providing reliable and energy-efficient performance. The Indirect-Fired Warm Air Generator exemplifies our commitment to advanced radiant heating solutions, ensuring optimal comfort and productivity in your workspace.

Contact Us for Customized Heating Solutions!

Ready to enhance your facility’s heating efficiency? Reach out to KeyWarm for expert advice and tailored factory heating solutions.

- Available in vertical or horizontal configurations, suitable for indoor or outdoor installation.

- Combustion is proportionally controlled, with a thermal efficiency exceeding 90%, resulting in energy savings.

- Multiple interlocking protection measures, including flameout protection, air pressure protection, overheat protection, and low gas pressure protection.

- Large combustion chamber design, small combustion chamber volume, low NOx emissions.

- Unique heat exchange tube design, increasing smoke disturbance, and achieving high heat exchange efficiency.

Here are the criteria to consider in selecting the units:

- Vertical or horizontal units;

- Indoor or outdoor applications

- Fuel types, such as natural gas, propane, diesel and etc.

- Max. static pressure of centrifugal blower(s)

- Heating power

- Air flow rate

To start with the installation, it’s best to begin with a pre-installation checklist (a list of items to check before installation). The following is a basic checklist, intended as an example:

- Choose a suitable location for installing the heater.

- Ensure that ventilation requirements can be met.

- Examine any issues that may affect the installation of HVAC, plumbing, and electrical systems.

- Design and plan the correct fuel supply pipeline.

- Design and plan the correct supply and return air ducts (if necessary).

- Check the minimum distance from combustible materials in accordance with manufacturer recommendations and local regulations.

- Ensure equipment is easily accessible for maintenance.