APPLICATIONS

Industrial Heating Uses

- Warehouses

- Factories

- Air Hangers

- Railway Stations

- Gymnasiums

- Exhibition Halls

ADVANTAGES

- Energy-efficient: Saves 30% gas and 50% electricity compared to traditional convection heating.

- Clean: No air disturbance.

- Quiet: No noise

- Safe: Gas pipelines do not enter the interior, with lower requirements for buildling fire safety.

HOW IT WORKS

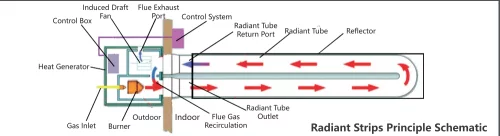

The infrared gas heater burner generates high-temperature flue gas by burning natural gas or propane. Driven by the induced draft fan, the flue gas flows along the gas infrared tube heaters, heating the surface of the radiant tube to a consistent temperature. The radiant tube and reflector emit infrared radiant heat, warming objects or the ground below through radiation to achieve effective and uniform heating.

The radiant heater system consists of the main unit (including the burner, combustion chamber, centrifugal circulation induced draft fan, etc.), ceramic infrared heaters or metallic radiant tube, reflector, control system, and other integrated components.

High-Performance Radiant Strips – Energy-Efficient Industrial Heating

Our Radiant Strips BP‑LTVU and BS‑LTSU Series provide powerful infrared heating for industrial and commercial applications, ensuring energy-efficient and uniform warmth. Designed for warehouses, factories, aircraft hangars, railway stations, and gymnasiums, these industrial infrared heaters deliver consistent performance while helping reduce energy consumption.

As trusted heating experts, we also supply ceramic infrared heaters, tube infrared heaters, and alternatives to Schwank models to meet various commercial infrared heaters requirements. Our systems emphasize fuel-efficient operation, long-term reliability, and simplified installation.

Looking for the best infrared heaters with bulk ordering and worldwide shipping?

Contact us today for a custom quote!

- BP series two-stage or BS series proportional combustion technology

- Heat-treated aluminized steel radiant tube

- Three-sided insulationfor the reflector

- The heat generator can be installed outdoors, ensuring safe combustion,and no need for indoor installation of a gas leak alarm system

- Installed at the top of the building, not occupying working space

- High-temperature flue gas recirculation combustion technology

- Gas and power lines are nstalled outdoors, reducing the building’s fire protection level

- Combustion uses outside air, with flue exhaust to the outside

- Intelligent temperature control: single-unit on-site control,

- PLC multi-unit group control on-site, or remote control (optional)

Heating Power:

- Warehouse: 80-110 W/sqm

- Factory: 120-180 W/sqm

Burner: Two-stage BP burner or modulating BS burner

Radiant strips module (pipe&reflector): Double pipe or single pipe

Controls: Local control or remote control

- Minimum distances to combustibles must be met, according to the manual.

- Installation is not recommended in places where there are chlorine products, solvents or explosives, but certain models are suitable for that type of environment.

- Enough expansion joints should be designed and installed.