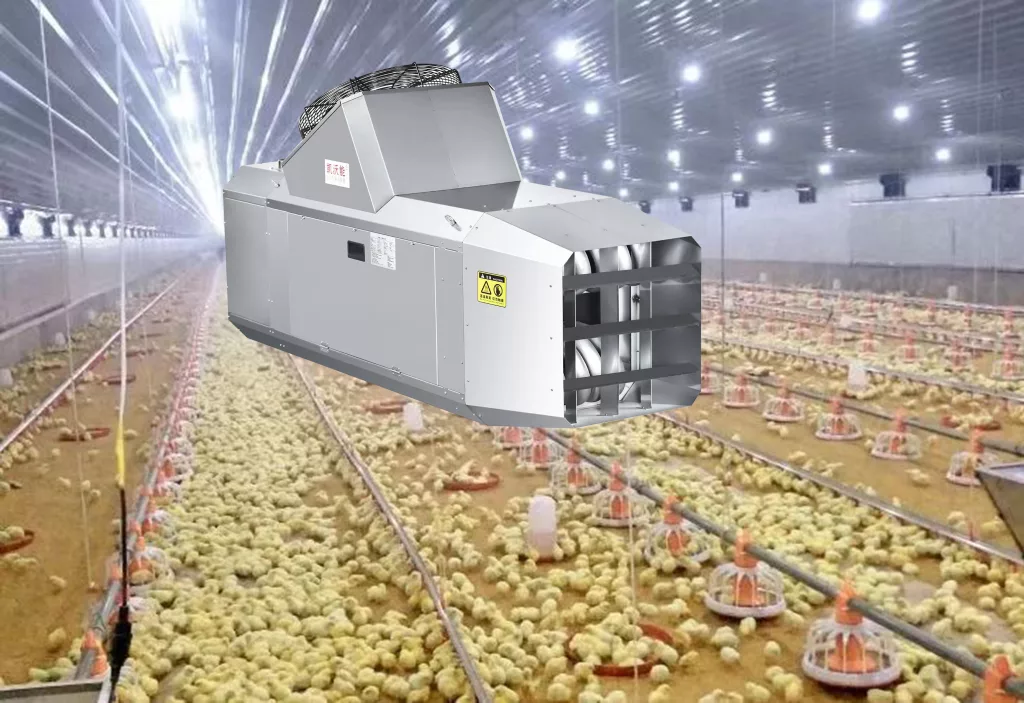

APPLICATIONS

Agricultural Heating Uses

- Greenhouses

- Swine houses

- Poultry houses

ADVANTAGES

- Easy to use and cost-effective.

- Simple installation and operation.

- High heating capacity.

- Simple to control with a thermostat or most environmental controllers.

- Exceptional reliability and durability.

- Easy maintenance.

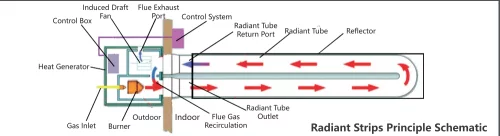

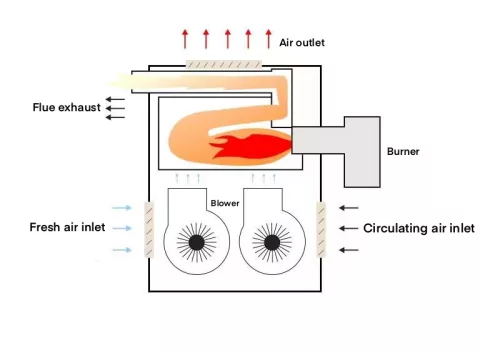

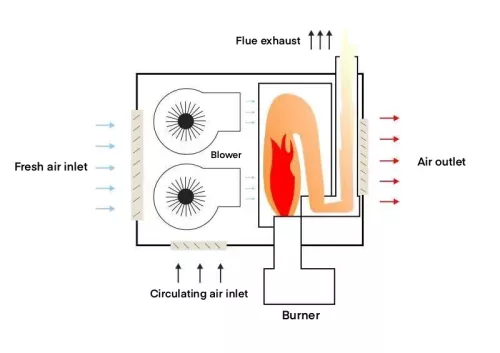

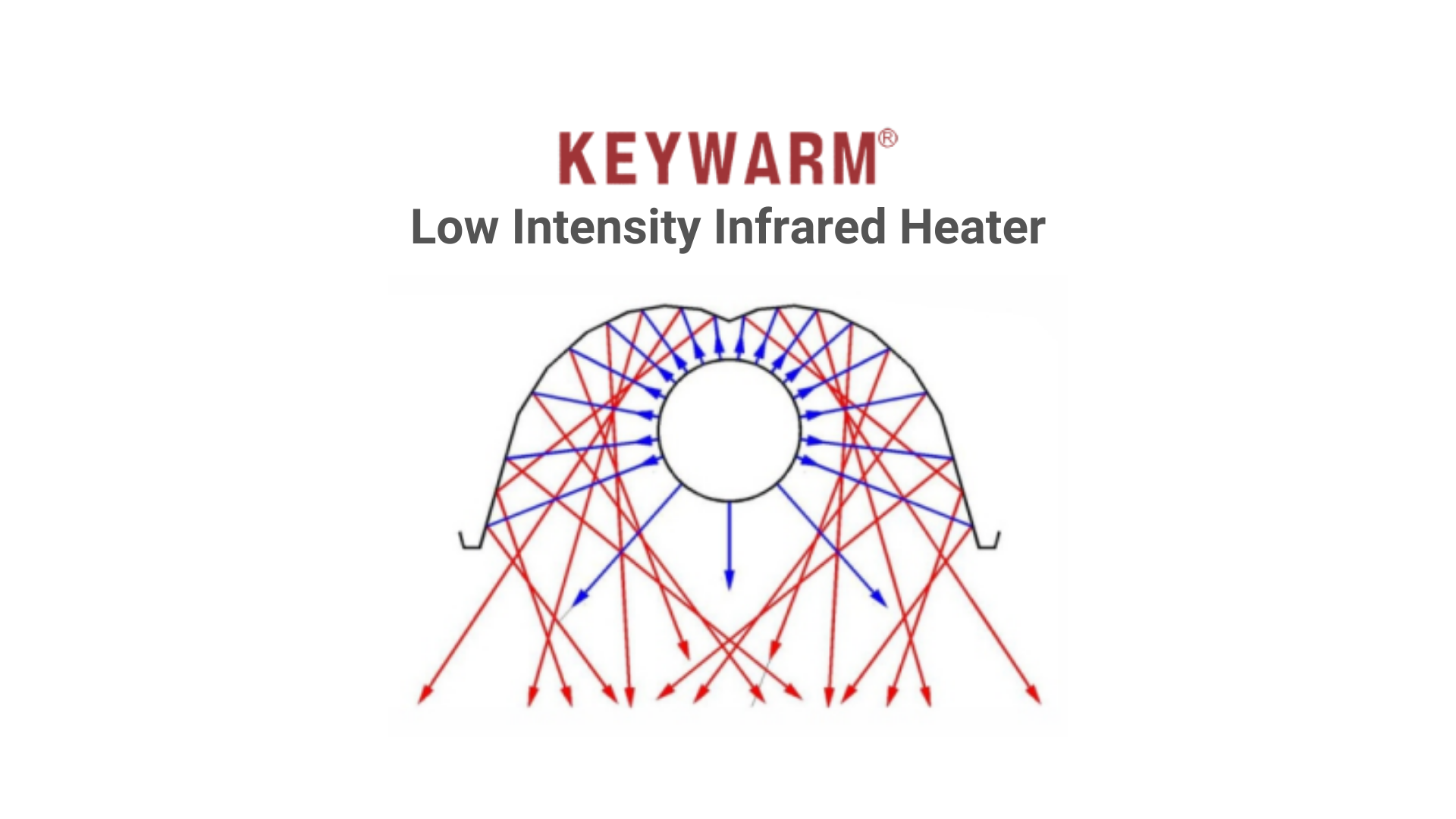

HOW IT WORKS

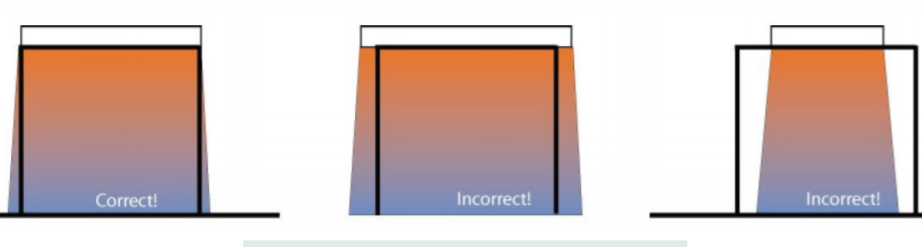

The thermostat calls for heating. The circulation fan starts and the ignition control system starts to ignite and burn. The combustion products are mixed with the heated circulating air to achieve the purpose of heating.

The air heater has an open combustion chamber, which means that all the heat from the combusted gas enters the room, ensuring 100% heater efficiency.

- Natural gas or LPG.

- Rates 50/70/100/120kW.

- The 12VAC low-voltage ignition controller, specially developed for HVAC industry, all troubleshoots can be easily identified by the indicator lights.

- Safer and reliable low-voltage 24 VAC combination gas valve with 100% shut off.

- Flameout protection, fan malfunction protection, and overheating protection.

- Indoors installation only.

1. Greenhouse size:

- Measure the total exterior surface area of your greenhouse in square feet. This includes walls, roof, and doors, but not the floor.

2. Heat loss factors:

- Identify the heat loss factor (U-factor) of your greenhouse materials. This value represents how readily heat escapes through the materials. Lower U-factors indicate better insulation.

- Common U-factors for greenhouse materials: – Single-layer plastic: 1.5-2.0 BTU/(hrft²°F) – Double-layer plastic: 0.75-1.0 BTU/(hrft²°F) – Glass: 1.0-1.5 BTU/(hrft²°F)

3. Temperature difference:

- Calculate the desired temperature difference (ΔT) between the inside and outside of your greenhouse. This is typically the minimum temperature you want to maintain inside minus the average outdoor temperature during the coldest period.

4. Heater output:

- BTU (British Thermal Units) measure the heating capacity of a heater. Use the following formula to calculate the required heater output (BTUH): BTUH = Surface Area (sq ft) * U-factor (BTU/(hrft²°F)) * ΔT (°F)

5. Safety margin:

- Add a safety margin of 10-20% to the calculated BTUH to account for heat loss through ventilation, infiltration, and other factors.

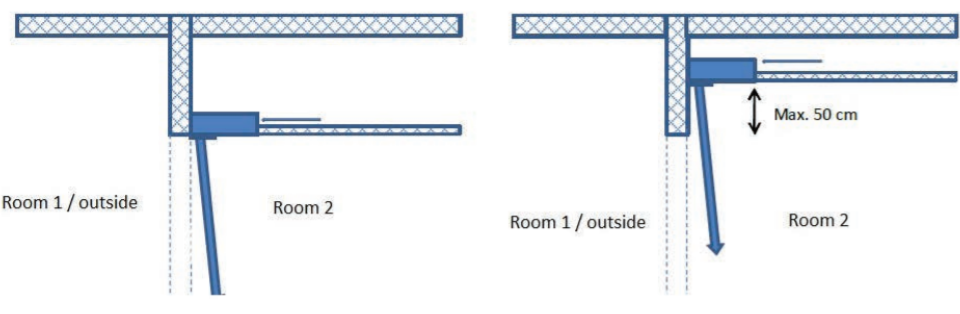

- Allow enough free space to the left and right of the air heater to enable maintenance and repair works to be carried out.

- The air heater must be connected to a reliably earthed and watertight wall socket at all times.

- The air heater must never be connected to a duct system.

- Inspect the air heater prior to use and check for damages.

- Avoid exposing the air heater to water and moisture for long periods of time.

- Keep the control instruments free from dirt and grease.

- Bear in mind that some parts of the air heater become hot during use.

- When the air heater is not used for long periods of time, remove the plug from the wall socked and shut off the gas supply.